Winders Winders

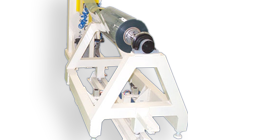

AUTOMATIC TURRET WINDER FOR PET – PS – PP FOIL EXTRUSION LINES.

Highly automated turret winders for winding up extruded or co-extruded fl at foil to be subsequently thermoformed.

Being equipped with high-tech differential shafts, the latest concept turret winders of the RW series are intended for building up one or more reels on the same axle, ensuring constant winding tension and reel compactness all along its entire width.

End-reel transverse cut and foil taking up on the new winding shaft are automatically executed in a totally guarded machine area, thus ensuring full safety of the operating personnel.

Automatic detection of the installed shaft diameter (3” – 6” or 8” as a standard) is also provided, with consequent self-confi guration of

optimized process parameters and errors minimization.

Reel is automatically downloaded from the winding station onto a movable cart, ready for subsequent weighing and removal.

The system modularity enables easy winder interface with automated equipment for reel selection and distribution.

Shaft repositioning is fully automatic.

Automation is SIEMENS PLC S7-300 based with touch-screen type Operator Panel, complete with communication network for

extrusion line interfacing and central remote assistance. Accuracy in software development has enhanced control on winding tension

through careful electronic compensation of static and dynamic frictions.

The technological solutions implemented in mechanical engineering and software development have rendered RW turret winders capable of granting utmost precision of fi nal product. At machinery design stage, great attention has been focused on the basic aspect of operator safety and health. Such target has been reached through the installation of accurate mechanical and electronic safety systems combined with elevated automation in machine operation.

Side trimmers and central cutters for foil division in two or more webs are available. MTG can count upon business partnership with

worldly acknowledged leading manufacturers to offer top-quality cutting equipment, prolonged service life of cutting blades and rapidity of blade replacement.

The employ of patented safeguards maximize operator protection and drastically reduce injuries and accidents in a potentially hazardous zone of the extrusion line.

Other Products

Questions?

- +39 035 894376

- +39 035 894350

- info@tecnowinding.com

- Via Basella, 849 – 24059 URGNANO (BG) | ITALY